In the aluminum melting industry, the quality of molten aluminum is directly related to the quality of the final product. As one of the key technologies to improve the quality of molten aluminum. Online degassing equipment is attracting more and more attention from enterprises. This equipment can not only remove hydrogen and other gases in molten aluminum, but also effectively reduce the inclusion content. Thereby significantly improving the performance and yield of aluminum alloy products.

Advantages of online degassing equipment designed and produced by Henan Chuanghui(Aoriek) :

1. Efficient degassing

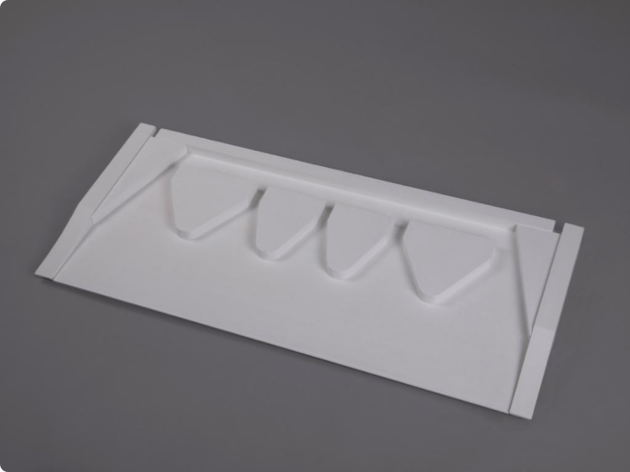

The degassing principle is to use one or more degassing rotors to introduce inert gas, into the bottom during the smelting process. The inert gas is broken into a large number of dispersed bubbles. Under the action of the high-speed rotating rotor and enters the molten aluminum. It is adsorbed together with hydrogen and oxidized slag in the molten aluminum, and floats to form slag on the surface of the molten aluminum. The refined molten aluminum flows out from the outlet of the degassing equipment, that is, the purpose of continuous online refining is achieved.

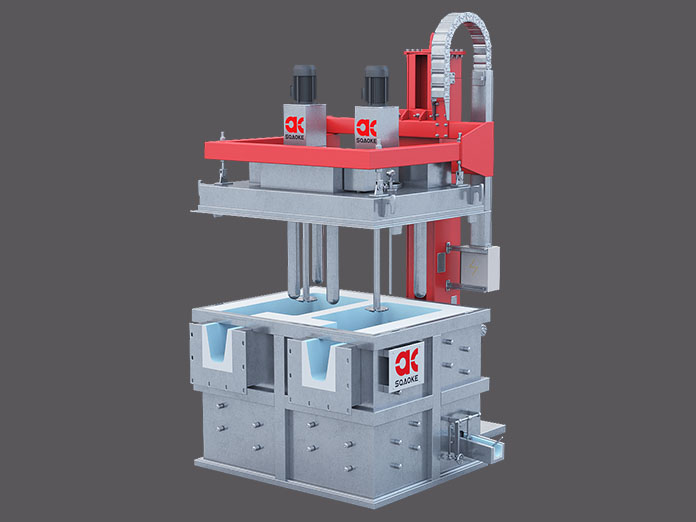

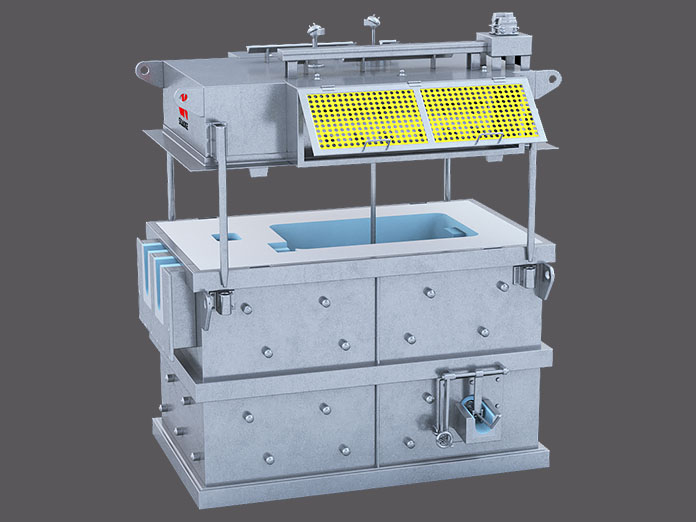

2. Structural optimization

The design of the equipment includes key components such as the processing box, lifting system, heating system, rotor and control system. The processing box is made of imported castable lining, to ensure the durability and thermal insulation performance of the equipment. The rotor is made of composite materials such as SiC, Si₃N₄ and graphite. It has good thermal shock resistance, wear resistance, corrosion resistance and long service life. It will not wear and the degassing efficiency will not change under normal operation, so it can ensure long-term and stable degassing effect. The design of the rotor also uses centrifugal force to further enhance the degassing effect.

3. Energy saving and consumption reduction

The heating system of the equipment adopts advanced temperature control technology, which can achieve precise temperature control and reduce energy consumption. At the same time, the equipment has good sealing, which reduces heat loss and reduces production costs.

4. Intelligent control

The equipped control system can realize automatic control of gas and electricity, is easy to operate, and improves the automation level of production.

5. Environmentally friendly

During the degassing process, nitrogen is introduced into the surface of the molten aluminum for protection, which reduces pollution to the environment, and meets the requirements of modern industrial production for environmental protection.

6. Wide application

This equipment is not only suitable for aluminum production, but also has a wide range of applications in military, aviation, aerospace and other industries. It is of great significance to improve the production of high-performance aluminum alloy materials.

Henan Chuanghui(Aoriek) group 's online degassing equipment has the characteristics of high efficiency, energy saving and environmental protection. It not only improves the quality of aluminum ally, but also saves production costs for enterprises and improves market competitiveness. Henan Chuanghui(Aoriek) group's online degassing equipment is your best choice to improve the quality of molten aluminum and achieve high-quality development. We serve with our heart, just to help you create more value! Take action quickly, join hands with us, and create a better future!

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.