product

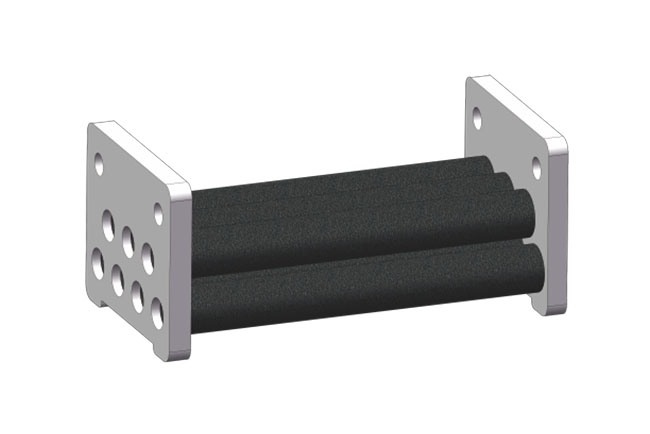

Tubular filtration equipment is installed between CFF filtration equipment and rolling mill.

Tubular filtration equipment is installed between CFF filtration equipment and the rolling mill. First filtration,needle-like protrusions on the surface of the filter tube will capture the particle inclusions. Second filtration, fine oxidized inclusion particles in molten aluminum will be absorbed by the medium inside the filter tubes. This double-filter process can purify molten aluminum to meet high filtration requirements.

Chuanghui tubular filter equipment aims to provide a larger contact area in a smaller space, so as to form a high filter medium surface, which improves the filtration effect. The highest tube group can remove more than 98% of all impurity particles above 5μm.

Tubular filter equipment can greatly improve the metal quality, and it is the highest level of high-precision filter devices.

| Heating mode | (KW)E-heating | Temp Control Mode | PLC control,instrument control |

| Shell average temp | ≤45℃ | Al melt temp in the box | 680-800℃ |

| Average warming capacity | 20P/hr (with Al melt) | Temp control accuracy | ±2℃ (static) |

Chuanghui filter tube group introduced Japan technology and imported materials R & D and manufacturing, is one of the only two companies in the world which produce such products, Chuanghui tube group unique micropore structure and micropore fineness, provides a good guarantee for the filtration efficiency.

| filter tube grade | RA | RB | RC | RD | RE |

| average pore dia(um) | 740 | 620 | 460 | 350 | 260 |

| average particle dia(um) | 1680 | 1190 | 930 | 710 | 600 |

| average flow speed | 20 | 16 | 16 | 7-12 | 7 |

| service life (t/pc)each filter tube | 100-150 | 50-100 | 15-50 | 10-15 | 10 |

| removeble partical size (um) | 100 | 50 | 30 | 10 | 5 |